Automatic 1-10kg ice cube bag forming filling packaging machine

Introduction :

This unit machine is special design for packaging ice cube ice tube .The whole machine body made by SUS304 .Including one set ice cube feeding conveyor ,ice cube weighing filling machine ,VFFS bag forming sealing packaging machine ,one set platform for weighing machine and output conveyor for transfer the finished bag.According client requirement we can add handle hole punching device .

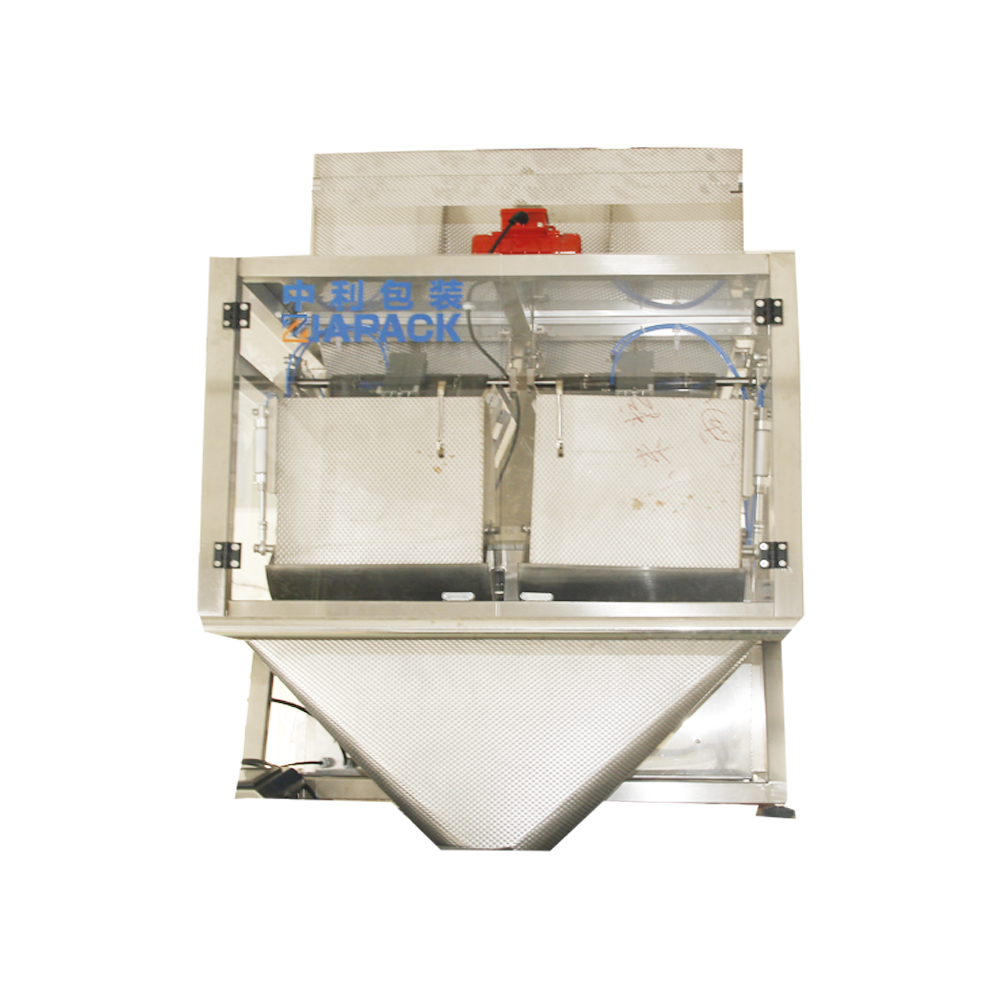

ZLC2-15LTwo buckets double feeding weighing machine

Introduction :

This linear weight is dosing system for ice cube .With double weighing bucket volume .Each bucket can weighing ice cube 1-5kg .Once double bucket discharge once the total weight can be 10kg /bag .The whole machine body made by sus304,Control by colorful touch screen which can be easy setting different parameter . This machine can store up to 50 different recipes, allowing customers to quickly switch between different weight.

Xususiyatlari:

- 7” color touch screen with multi-language operating system. Software can be upgraded through USB.

- SUS304 body structure for option. High performance ondust and water proof design.

- Restoration function of factory parameter. 99 product parameters can be preset to meet different parameter program requirements.

- Amplitude can be automatically adjusted for easy operation.

- Each hopper can be used as single weighter.

- Able to weigh and pack two different products.

- With cylinder controlfor door open-close control , which is faster and more stable.

- Modular control system for easy maintenance and cost-saving.

Parameter:

Weighing range:1000gram-10000gram

Accuracy :±0.3-0.5%

Min scale :1gram

Max speed :3-15bag/min

Buffer Volume:25L

Weighing bucket :11L

HIM:7” touch screen

Power supply :AC220±10% 50HZ /60HZ 1KW

ZL900 VFFS BAG FORMING FILLING SEALING PACKAGING MACHINE

This machine equipped with bag-making, cutting, code printing , etc.Control by Siemens PLC and operating on Siemens Touch Screen,Panasonic servo motor, Japanese Photo Sensor , Korean Air valve,. The film pulling system adopted servo motor driving making speed faster . The film pulling system adopted servo motor driving which more stable in humid environment.

Texnik parametrlar:

Weighing Range: 1kg-10kg

Packaging Speed:10-20 bags/min

Bag size: (220-550)*(180-430)mm(L*W)

Max film width:900mm

Compressed air requirement: 0.6Mpa 0.65m³/min

Reel outer diameter: 450mm

Core inner diameter: 75mm

Machine weight: 950kg

Power source: 6.5kW 380V±10% 50Hz

Main Features and Characteristics:

- A wide range of pouches: Pillowbag

- High speed: 5-20bags/min

- Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

- Oson sozlanishi: har xil paketlarni o'zgartirish uchun faqat taxminan 10 daqiqa.

- Chastotani nazorat qilish: tezlik oralig'idagi chastota konvertatsiyasi bo'yicha sozlanishi mumkin.

- Yuqori avtomatlashtirish: tortish va qadoqlash jarayonida insonsiz, avtoulovni avtomatik ravishda ishlamay qolganda.

- Safety and Hygiene:

- No film, machine will alarm.

- Mashina signalizatsiyasi va havo bosimi kam bo'lganda to'xtaydi.

- Xavfsizlik himoyasi bilan jihozlangan xavfsizlik qo'riqchilari, xavfsizlik apparatlari ochilgan paytda mashina signallari va to'xtash joylari.

- Hygienic construction, the product contact parts are adopted sus304stainless steel